TRUMPF’s punch laser processing cell the TruMatic 5000 with the new SheetMaster

Imagine a manufacturing world where versatility, precision, and efficiency converge seamlessly, transforming the way you approach sheet metal fabrication, read more…

Welcome to Headland Technology Client log in

Whether you’re after a machine, spare part, power tool, or need to book a service call Headland will help you find the right solution in a timely manner.

Fill out the form below and the relevant expert will be in touch with you shortly.

We represent cutting edge machine technology that’ll help you achieve a competitive advantage in your manufacturing process.

Sheet metal fabrication machines from TRUMPF, JFY and Timesavers. Laser cutting, tube lasers, punching machines, press brakes, welding and deburring machines.

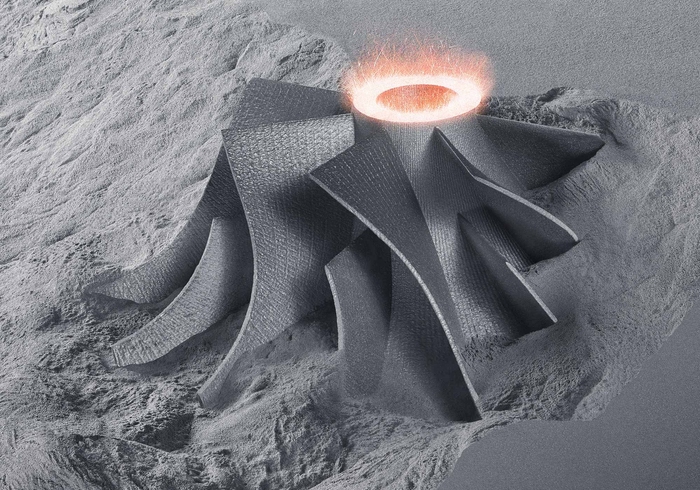

Metal additive manufacturing machines for sale in Australia and New Zealand from TRUMPF. 3D metal printing and laser deposition welding.

Plastic machining solutions for sale in Australia and New Zealand. Injection Moulding and Extrusion machines from KraussMaffei and Netstal.

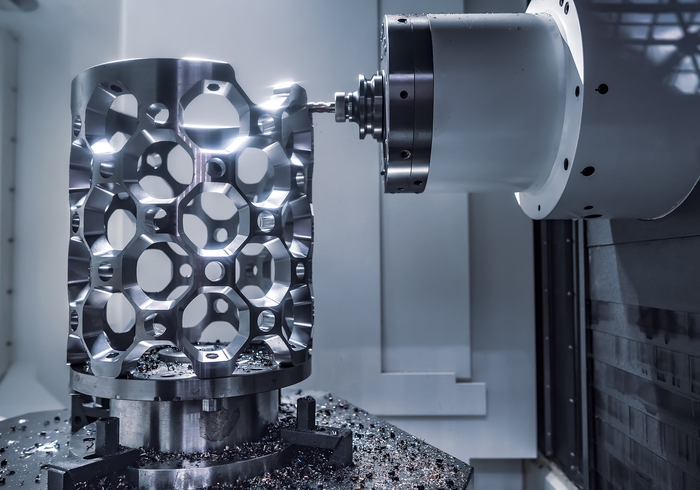

CNC machines for sale in Australia and New Zealand. Vertical and horizontal machining centers, CNC Lathes, milling machines.

Automated Warehouse Storage for sale in Australia and New Zealand. Hanel and STOPA storage systems.

High performance metal fabrication machinery range including machinery from TECOI, Timesavers, SOCO and more.

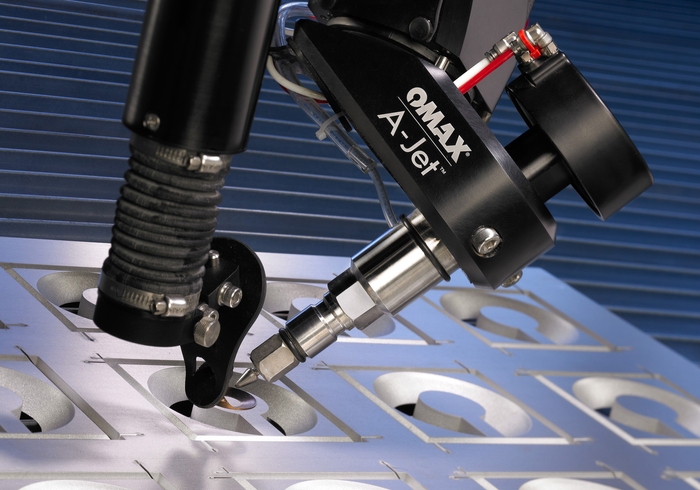

Water jet cutting machines for sale in Australia. Our water jets can cut steel, stone, glass, rubber, plastic & more.

TRUMPF Power Tools for sale in Australia and New Zealand. Electric and battery-powered tools for sheet metal applications and beyond.

Rowland MetalWorks hired Headland Technology to come in as a consultant entity to review and analyse its manufacturing processes and to help identify the right equipment or technology and possibly implement them in a way that would maximise their profits over the term of 5 years.

We interviewed Darren Baills from Stoddart on their journey towards a smart factory.

Tristan Opie believes TRUMPF produces the best and most reliable sheet metal manufacturing technology.

Smart factory solutions bring a paradigm shift to the manufacturing and production landscapes. Smart factories run digitalised, automated systems that improve operational efficiency and connectivity.

Such systems bring the power of artificial intelligence, machine learning, IoT, and AR to create an integrated ecosystem that connects devices and manufacturing equipment.

Imagine a manufacturing world where versatility, precision, and efficiency converge seamlessly, transforming the way you approach sheet metal fabrication, read more…

Find out how our Team expands across sales, finance, and tech roles and updates on training, events, and our current in-stock machines.

Discover how a pharmaceutical company effectively leveraged Hanel’s advanced storage solutions to address the issues of storage efficiency and space optimisation.

Whether your enquiry is about a machine or service-related, we promise to help you find a solution as quickly as possible.

Please fill in the form and click submit. Once the form is submitted one of our experts will be in touch with you shortly.