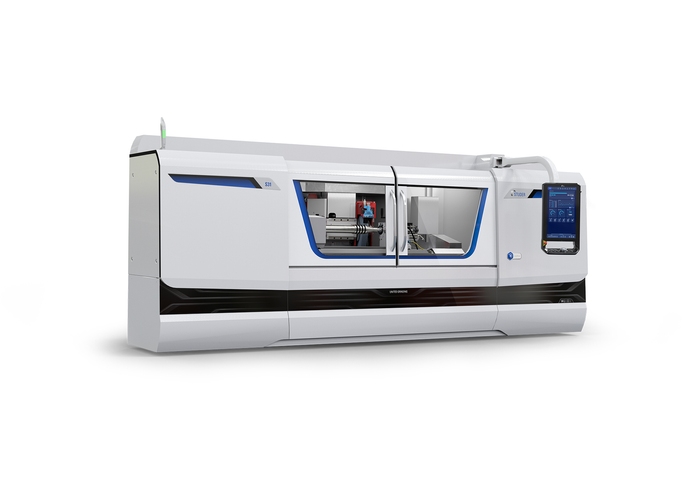

The InsertLoad automation solution, launched by STUDER, has transformed the loading and unloading process for Studer’s S33 and S31 universal cylindrical grinding machines. This innovative system enables standardised automation, eliminating the need for customised solutions. With its versatility, InsertLoad can handle workpieces between centres and into the chuck, making it an ideal solution for various industries in Australia and New Zealand.

The perfect blend of standardisation and flexibility

The InsertLoad system combines the advantages of standardisation with flexibility, making it an attractive solution for manufacturers. It can handle a wide range of parts with varying geometries, weights, and sizes. The capacity of the drawers and the degree of autonomy can be adapted to meet specific needs and requirements. The loading and unloading process is efficiently handled by a Fanuc robot, which moves independently on a linear axis between the loader and the machine’s work area. This autonomous operation can last between thirty and sixty minutes without human intervention.

Safety features

STUDER prioritised safety during the development of InsertLoad with a loading hatch separating the loading area from the machine’s working area, preventing flame flashback during machining processes using grinding oil. Additionally, the software and a safety switch ensure the safety of grinding technicians in the event of a deflagration.

Availability and future plans

The InsertLoad system was showcased at the EMO trade show in Hannover, Germany, it is available for the S33 and S31 CNC universal cylindrical grinding machines, but Studer plans are underway to expand its availability to other models. The S33 and S31 machines are ideal for grinding small to large workpieces in single, small batches, and volume production. With InsertLoad, manufacturers in Australia and New Zealand can streamline their loading and unloading processes, increasing efficiency and productivity. Its flexibility, safety features, and ease of use make it an attractive solution for various industries.

InsertLoad at a glance:

- Efficient standard solution

- Universal use

- Operation through the setup wizard

- Loading between centres or in a chuck

- Full integration in machine design

Are you interested in learning more about the Studer’s InsertLoad automation solution and how it can benefit your operations?

Contact Headland Technology’s experts today to discuss your needs and discover how STUDER’s new universal loading system for cylindrical grinding machines can enhance your production capabilities.