InspecVision, a valued partner of Headland Technology, has recently showcased at TRUMPF’s INTECH event held at TRUMPF HQ in Ditzingen, Germany. Their cutting-edge automated measurement and inspection solutions have not only garnered attention internationally but are also highly relevant to the Australian and New Zealand market and the company has been shortlisted for two prestigious awards in Northern Ireland: the Belfast Telegraph Business Awards and the Made in Northern Ireland Manufacturing Awards.

The Belfast Telegraph Business Awards, renowned for celebrating the best in local business, have acknowledged InspecVision’s achievements in exporting their technology. Being shortlisted in these awards underscores InspecVision’s role as a leader in technological advancements and their impact on the local economy.

Similarly, the Made in Northern Ireland Awards nomination highlights InspecVision’s excellence in international trade, emphasising its prowess in developing and exporting advanced technologies from Northern Ireland to the global market. These nominations not only enhance InspecVision’s reputation but also reaffirm its position as a key player in the international manufacturing landscape.

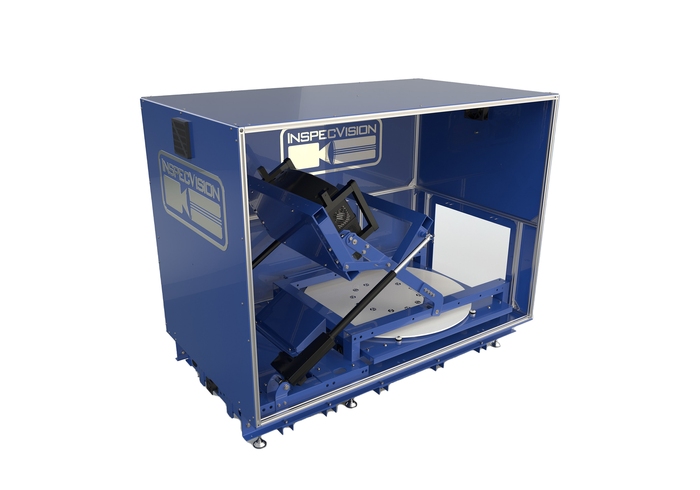

Planar 2D and Opti-Scan 3D for quality control in manufacturing

At INTECH, an exclusive four-day showcase of TRUMPF’s innovative manufacturing technology, InspecVision, as a TRUMPF Solutions Partner, presented their automated 2D & 3D inspection and reverse engineering technologies that are designed to improve efficiency and accuracy in sheet metal production, aligning perfectly with the needs of manufacturers in Australia and New Zealand.

InspecVision’s participation provided a platform to demonstrate their flagship products, such as the Planar 2D inspection system and the Opti-Scan 3D, which have revolutionised the way manufacturers perform quality control. The Planar 2D system, known for its speed and precision, can automatically inspect multiple parts in seconds. Meanwhile, the Opti-Scan 3D, equipped with advanced scanning technology, offers detailed and efficient 3D inspections, making it an indispensable tool for quality assurance in manufacturing.

Do you want to elevate your manufacturing quality control processes?

For Australian and New Zealand manufacturers, partnering with InspecVision through Headland Technology opens doors to advanced inspection solutions that can streamline production processes, improve product quality, and ultimately drive business success. Contact Headland’s experts today to explore how InspecVision’s cutting-edge technologies can benefit your operations in Australia and New Zealand.