Plastic extrusion is a manufacturing process that has revolutionised the manufacture of everyday items ranging from pipes and tubing to window frames. It is utilised across numerous industries, including packaging, construction, automotive, and more.

What is a plastic extrusion machine?

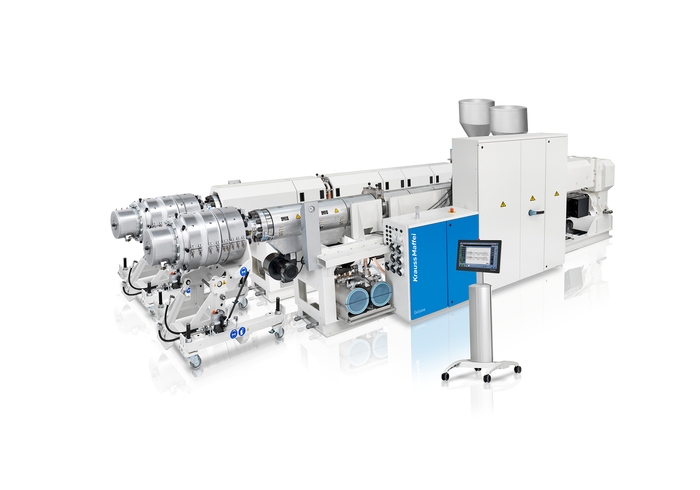

A plastic extrusion machine is a device that melts and shapes plastic materials into continuous profiles. The process involves feeding plastic pellets or granules into a heated barrel, where they are melted and mixed. The molten plastic is then forced through a die, which shapes the material into the desired profile. The extruded plastic is cooled, solidified, and cut to the required length.

Key components of a plastic extrusion machine

Extruder: The extruder is the heart of the machine, consisting of a barrel, screw, and drive system. It melts and mixes the plastic material before pushing it through the die.

Die: The die is a custom-designed tool that shapes the molten plastic into the desired profile. Dies can be changed to create different shapes and sizes.

Cooling system: After extrusion, the hot plastic profile is cooled and solidified using a cooling system, such as water baths or air cooling.

Haul-off and cutting units: These units pull the extruded plastic profile and cut it into desired lengths for further processing or packaging.

Preparation of raw materials for plastic extrusion

The process starts with the preparation of raw materials, usually plastic resin pellets or granules. These pellets are often made from polymers like polyethylene (PE), polypropylene (PP), polystyrene (PS), or PVC (polyvinyl chloride).

- Melting: The plastic pellets are fed into a hopper, which then feeds them into a heated barrel. Inside the barrel, there is a screw mechanism that rotates and pushes the pellets forward while simultaneously heating them. The friction generated by the rotating screw and the internal heat melts the plastic.

- Homogenisation and mixing: As the plastic melts, it becomes a homogeneous molten mass. Additives such as colourants, stabilisers, or reinforcing agents can be introduced into the molten plastic to achieve desired properties or appearances. The screw’s design ensures thorough mixing and distribution of additives.

- Extrusion die: Once the plastic is fully molten and mixed, it is forced through a specially shaped opening called an extrusion die. The die imparts the desired shape and size to the extruded plastic. Dies come in various shapes and sizes depending on the final product specifications.

- Cooling: As the plastic exits the die, it enters a cooling zone. Cooling can be accomplished through various methods, such as air cooling or water cooling. Rapid cooling helps solidify the plastic into its final shape. Cooling also sets the plastic’s mechanical properties.

- Sizing and cutting: After cooling, the extruded plastic is passed through sizing equipment, which ensures the final product meets dimensional specifications. Depending on the application, the extrusion may be cut into specific lengths using saws or blades.

- Finishing operations: Once cut, the extruded plastic may undergo additional finishing operations, such as surface treatment, printing, or coating. These processes enhance the appearance or functionality of the final product.

- Quality control: Throughout the extrusion process, quality control measures are implemented to ensure the final product meets quality standards. This may include monitoring parameters like temperature, pressure, and dimensions.

- Packaging and distribution: Finally, the finished extruded products are packaged and prepared for distribution to customers or further processing in downstream manufacturing operations.

Plastic extrusion offers several advantages, including high production rates, low cost per unit, and the ability to create complex shapes with consistent quality. Its versatility makes it a widely used manufacturing process across various industries.

Are you a plastics manufacturer looking to optimise your plastics extrusion operations and produce a wider variety of high-quality products more efficiently?

If so, contact Headland Technology’s experts to leverage our specialised KraussMaffei extrusion machine solutions. We can guide you through the latest extrusion technology advancements.