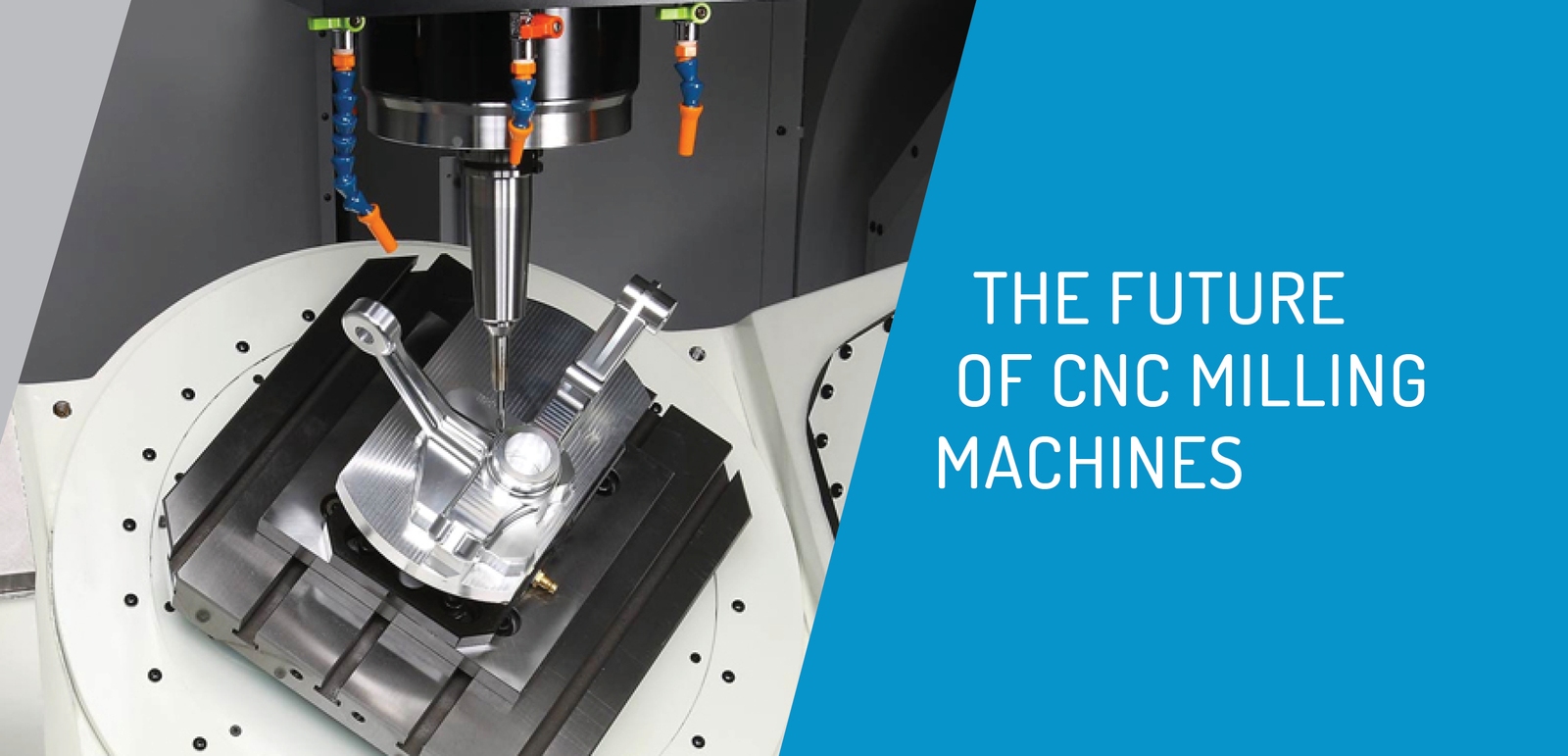

As CNC milling machine technology becomes increasingly more sophisticated by the second thanks to Industry 4.0, it is difficult to predict in what direction they will next advance – how will the technology adapt?

How will these changes impact on manufacturing processes and the manufacturers who utilise them?

So, what’s in store for the future of CNC milling machines? We explore below.

What is a CNC Milling Machine?

Before we really begin to analyse the future trends in CNC milling technology, let’s first define what exactly a CNC machine is.

‘CNC’ is an acronym that stands for ‘Computer Numerical Control’. These machines have become increasingly popular over the last couple of decades, their primary role being to supply manufacturers with the technological tools to keep up with the competition, and indeed, CNC machines allow users to dramatically increase their productivity levels while still maintaining optimum quality thanks to an automated system.

Milling machines are typically used for drilling, cutting and boring in the manufacturing process. The computer numerical control aspect, fused with the traditional milling machine creates an automated process which does not need as much human intervention as in traditional methods.

Compact in Size

As technology advances, it is clear that CNC machines are getting smaller and more compact. This makes storage of these machines easier, which enables more people to use them given that space is no longer a compromising factor when considering investing in one of these machines. Along with being more portable, an added benefit of a more compact machine is their ability to connect to other small machines as part of the manufacturing process. This move to being more compact echoes our mobile phones, laptops and pedometers, and is likely to become easily customisable based on user and industry preferences.

More Affordable

As well as becoming smaller in size, the price tag on CNC milling machines is also decreasing, ensuring that people are able to invest in their own machinery and carry out production work on site, rather than having to outsource expensive work overseas.

Enables Employment Opportunities

Though it may seem that utilising a machine to carry out work would replace rather than create jobs, the opposite is in fact true. Though there is no need to hire people to carry out the work that the machine is doing (cutting/ boring / drilling etc.) new jobs roles will emerge requiring people to maintain the machine, supervise its production, examine the quality of its output, sales, installation and general troubleshooting.

Watch Out For: CNC 3D Printers

Further opportunities come to manufacturers in another form of emerging technology – 3D printers. In time, it will be commonplace to connect a machine for each part of the manufacturing process, beginning with the prototyping stage. 3D printers are fast becoming a hot topic in the manufacturing industry, enabling inventors and manufacturers alike to cheaply, quickly and efficiently test out their ideas by printing them, before investing in the materials and production expenses.

It is clear that CNC Milling Machines and their technological counterparts are going to change the face of manufacturing as we know it.