Deakin University, one of our long-standing partners in the education space, have seen tremendous value from OMAX Waterjet systems to assist students with their projects and create an educational experience more in line with industry best practices.

Luke Tyrell, Senior Technical Officer in the Mechanical Engineering Department believes access to the latest OMAX technology has made prototyping and designing parts for projects far easier for students.

Easily visualise prototypes

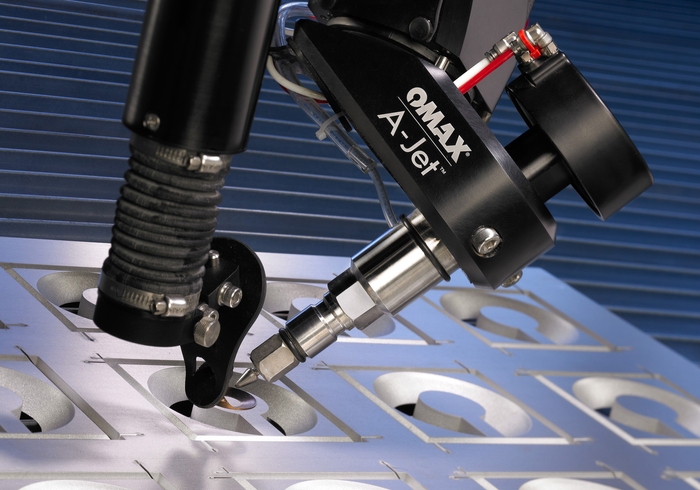

Luke thought the OMAX machine is an easy choice for his department as they showcase the best of software integration and ease of use. The IntelliMAX software that comes standard with every OMAX machine makes it easy to visualise prototypes and then show how 5-axis can be integrated into functional parts.

Another benefit of the OMAX machines, says Luke, are the continual software updates that in turn improve part quality and machining times for students.

Watch our interview with Luke:

[arve url=”https://www.youtube.com/watch?v=rbWtynP7na8&ab_channel=HeadlandTechnology” title=”Deakin University Omax Case Study” loop=”no” muted=”no” /]

Advanced CAM software

The OMAX machine’s ease of operation stems from its integration with IntelliCAM. This highly advanced CAM software makes picking 5-axis geometries super easy from the design through to manufacturing.

Headland’s commitment to education

Deakin has bought multiple machines from Headland and have benefitted from our application support and general machine reliability.

Headland’s goal is to provide easy-to-use, cost-effective, reliable, and high-quality abrasive-jet machining systems to the education industry. We have many long-standing relationships in the Australian education sector, providing them with cutting edge manufacturing technology.