Timesavers’ demonstrations of their deburring, edge rounding, finishing machines.

Series demonstrated include; the 10, 12, 22, 32 and 42 Series.

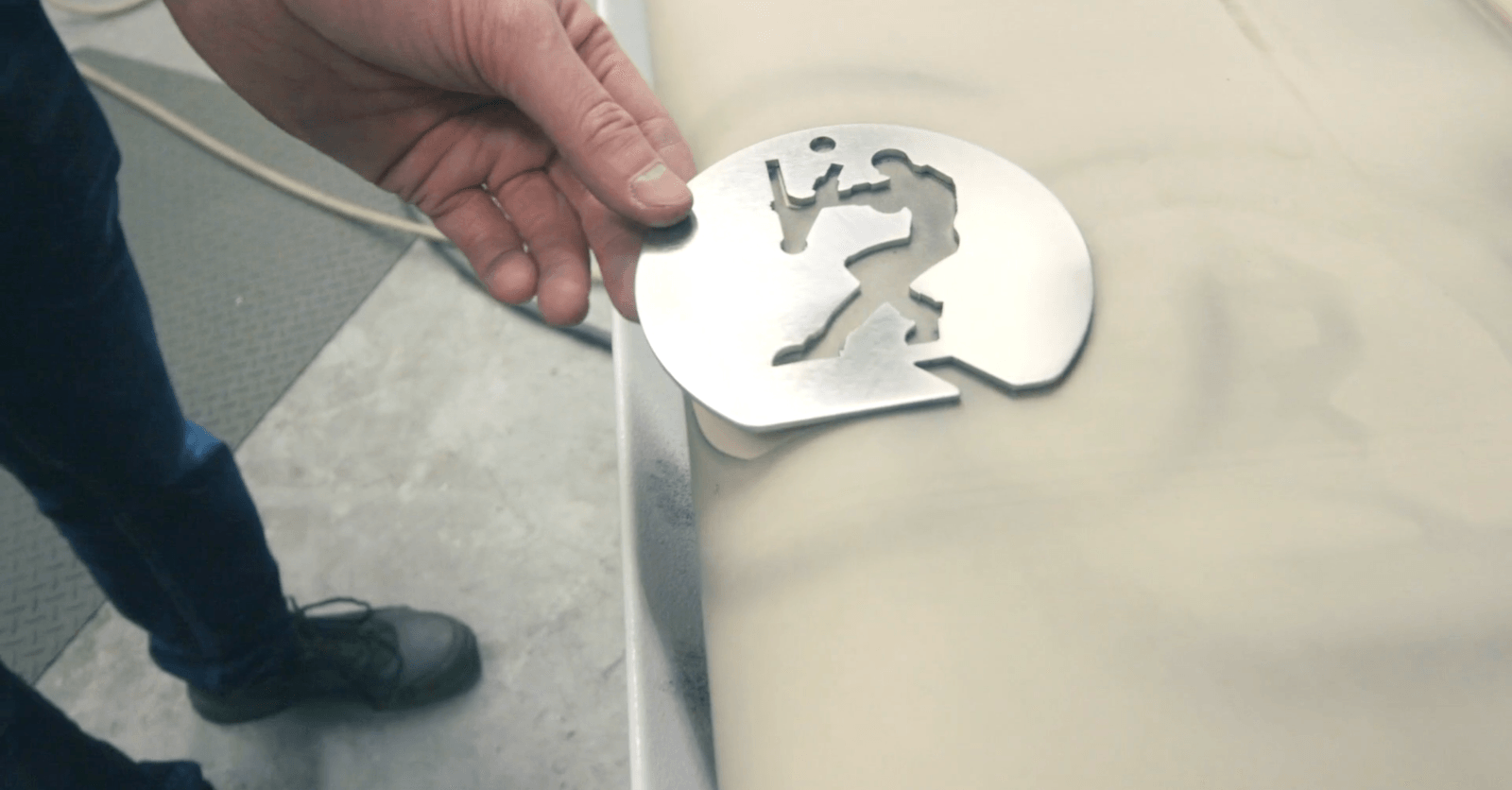

In these video demonstrations the Timesavers’ Sales Team walk you through how a deburring machine works, how the machine levels out and deburrs the material away to leave a smooth end product. Oscar also demonstrates the end deburred product on several material types including sheet metal, copper and aluminium.

Timesavers 10 Series

The Timesavers 10 Series is a rage of machinery that is a good entry point and a significant step up from manual deburring. It’s ideal for deburring, edge rounding and finishing of metal, a mirror finish can also be created. You can easily switch between deburring tasks with its 180 degree rotating shaft.

[arve url=”https://www.youtube.com/embed/Kz1mXr_xatM” title=”Timesavers 10 Series Complete – How Deburring Machines Work and How they Finish Metal” description=”The 10 series is Timesavers’ versatile starter model and the cost saving alternative for manual deburring, edge rounding and/or finishing of metal.” upload_date=”20/05/2020″ /]

[arve url=”https://www.youtube.com/embed/wOCP1erdcVU” title=”Timesavers 10 series Hammerhead – The Hammerhead Feature for Removal of Heavy Slag” description=”An aggregate for the removal of heavy slag on the Timesaver Deburring machines, consists of replaceable flexible pins to remove the heavy slag on plasma cut steel parts.” /]

Timesavers 12 Series

Available in 225 and 600 mm suitable for small parts, deburring and finishing. This machine is suitable for deburring a variety of metals with its abrasive belt and disc. The disc on this machine ensures product edge rounding can be completed at the same time.

[arve url=”https://www.youtube.com/embed/xb-LCE8Kjso” title=”Timesavers 12 Series – Demonstration of the Deburring and Finishing Features of this Model” description=”The 12 series is available in 225 and 600 mm and is suitable for the deburring and finishing of small parts. This dry working deburring machine has an abrasive belt, disc or both and is suitable for deburring a large number of metal components.” /]

Timesavers 22 Series

This machine is available in three nominal widths: 900mm, 1050mm and 1280mm. This machine is suitable for dry finishing and deburring of metal. Various attachments can ensure this machine is versatile and can be applied to different applications.

[arve url=”https://www.youtube.com/embed/rB84o_jQE1A” title=”Timesavers 22 Series WRBW – Full Demonstration of Dry Finishing and Deburring of Metal.” description=”The 22 series is suitable for the dry finishing and deburring of metal. This versatile machine is available in three nominal widths: 900 mm, 1050 mm and 1280 mm. In total, three attachments can be used with the machine for several applications.” /]

Timesavers 32 Series

The compact and dry operating, 32 RB series, offers laser oxide removal in addition to deburring and edge rounding. This machine has been designed based upon the Red Dot Award winning 42 Series RB.

[arve url=”https://www.youtube.com/embed/ohYY1F6bC-M” title=”Timesavers 32 Series – A Compact Dry Working Edge Deburring” description=”The 32 RB series is a compact dry working machine for edge deburring, smoothing and/or finishing flat metal parts like stainless steel, mild steel, aluminium and copper parts. The machine has the same design as the Red Dot 2016 Award winning model the 42 RB series” /]

Timesavers 42 Series

The most popular and Red Dot Award winning machine. Available in 1350 mm and 1600 mm width, offering you the ability to create a rounding radius of up to no less than 2mm. This machine offers a high-end finish for manufacturers of premium products. A multi-rotating brush system with up to 8 brushes ensures your parts will be deburred uniformly and edges rounded to perfection.

[arve url=”https://www.youtube.com/embed/Nx1LrQ0Uawg” title=”Timesavers 42 series HWRB – The Ultimate Deburring, Edge Rounding and Finishing Machine” description=”This deburring machine consists of a broad range of options for a flawless deburring, perfect edge rounding and finishing and ultimate precision grinding.” /]