With a market size of over $2.6 billion dollars annually, hot runners are a hot industry to be in.

With over thirty years of experience Mastip is known as a pioneer and one of the top global manufacturers of hot runner solutions in the world.

Mastip manufactured hot runners enable their customers to precision mould components and parts for a diverse range of applications from low cost caps and closures through to precision component for the packaging, engineering, white goods, automotive, medical and electronics industries

Committed to R&D, Mastip “makes things better”

Mastip’s success is from hard work, dedication and focus on product innovation and Engineering excellence. Mastip continuously invest in R&D, new technology and training to develop and advance their product solutions.

Their value is seen in their commitment to affordability, unsurpassed front and backend service and true global product support in over 40 countries, with operations in New Zealand, USA, China and Europe.

What is a hot runner?

It is an assembly of high precision components that locates between a tool and the injection point. The hot runner is designed to keep the injected polymer material at its optimum working temperature, helping it to flow into every part of the tool and achieve the best structural and cosmetic product results.

Mastip invest in new technology to advance their products

To create these precision high-quality parts, Mastip has a long-standing relationship with Headland Machinery.

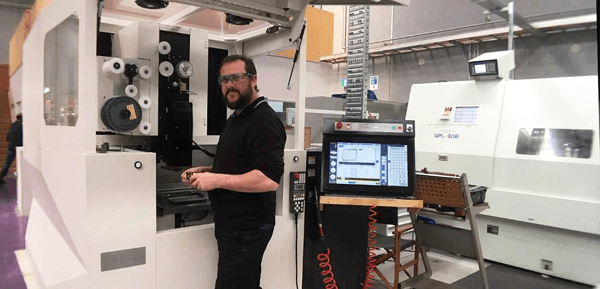

Earlier this year, Mastip installed a Nakamura-Tome WT-150II, making a total of seven Nakamura-Tome machines.

The Nakamura-Tome WT-150II is a high accuracy, high speed and high rigidity, multi-tasking machine with a compact foot print. This machine is ideal for the batch produced parts Mastip manufacturer.

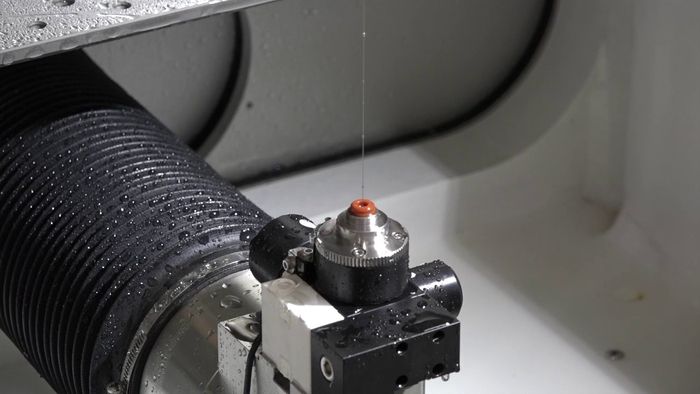

Additionally, in July 2018, Mastip installed a Makino U3 wire EDM, a high accuracy, compact machine with a user-friendly control system.

The Makino U3 is equipped with the HyperCut and Hyper-i control software. This software is easy to use, navigate and program, even for complex, geometric parts with high finishes.

Mastip CEO Marc Michel comments, “Mastip’s objective is to be world class and to achieve this we need world class partners which is what we have with Headland and their Makino and Nakamura machines”