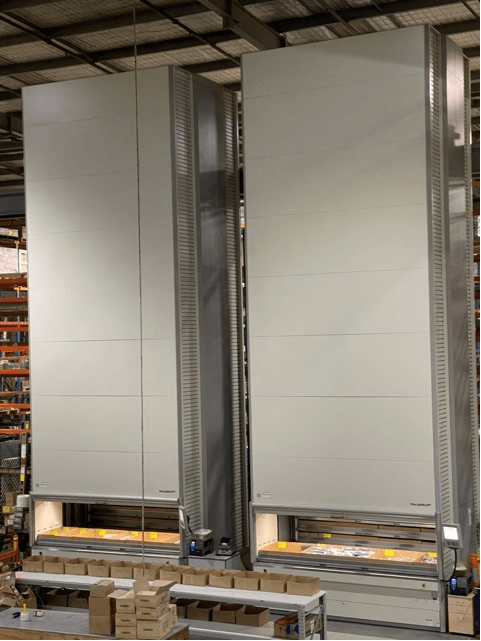

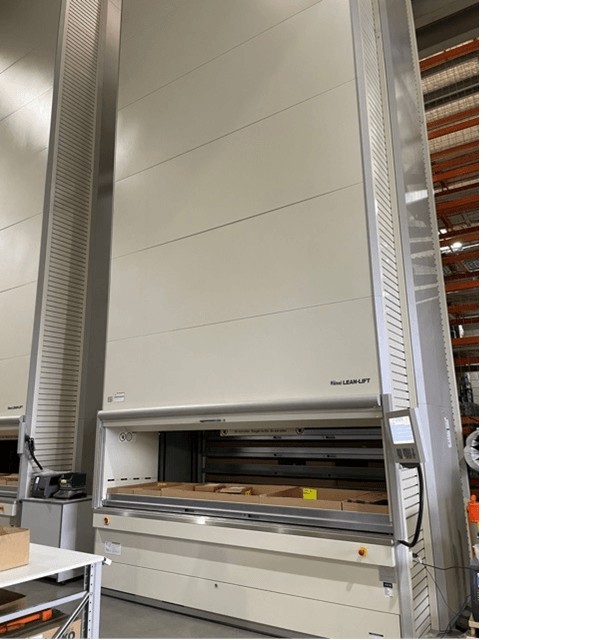

Case Study on Hänel Vertical Lifts

- Product: Hänel lean lifts

- Industry: Construction

- Company: Alspec Aluminium Systems Specialists, alspec.com.au

Headland recently spoke to Clinton Matthews, National Operations Manager about their recent purchase of the vertical storage machines, Hänel Lean Lifts.

Problem and Solution

HL: What was the key problem in your business that you were hoping to solve with the Hänel vertical Lean lifts?

CM: “Our main problem was capacity within an existing facility in conjunction with labour productivity; the time it was taking to fulfil orders through the picking process. Traditionally we would store our small components in traditional key lock racking systems and as such we were looking for a way to increase our productivity and increase the storage capacity of our existing facility. We have not had the systems long and we have already seen a reduction in excess of 22% in the time it takes to fulfil our orders.

The system also enabled us to pivot the existing operations with an increase in storage capacity by 25%. The introduction of the towers enabled us to store our small components to almost ten metres high, whilst recovering floor space for additional storage in our lineal based product.

HL: What parts are stored in the Hänel Vertical Lifts?

CM: “We store components for the windows and door frames we supply. Security is not a concern with our product line, it’s more about bringing goods to man, rather than man to goods. We focused primarily on improving our motions ways in the warehouse and increasing our usable floor space”.

Competitor Review

HL: Did you review the competitor offerings in the vertical lift space?”

CM: “Yes, we looked at this in detail, we reviewed not only the acquisition costs, but also the total costs of ownership, from depreciation to regular maintenance and support. We modelled our costing plan across a 15-year lifespan encompassing servicing and operating costs. We also reviewed the technical support located around Australia in conjunction with the positioning and quantity of spare part support.

Support from Headland

HL: Can you comment on the level of service you have received from Headland to date/what you think of the service team and sales team?

CM: “We worked with Frederik over a period of time to find the right solution for our business. Frederik is knowledgeable and helpful in finding the right product fit. He’s also focused on meeting our expectations as agreed prior to the sale.

“In terms of service we’ve received prompt support and the installation process went well with all Covid-19 induced challenges overcome with nil disruption to the installation and commissioning plan”.

HL: What are your thoughts on the construction industry?

CM: “It’s a high growth sector, for both the commercial and residential sector with no signal that the current work volumes will reduce in the immediate future.

About Alspec

HL: How long have you been in business and how have you grown over the years?

CM: “We’ve been in business for over 45 years with distribution facilities located across Australia.

“We have multiple businesses within the group and have in excess of 500 employees nationally supporting our customers with a fleet of company owned vehicles.

“We have In-house design and NATA accredited testing facilities assisting in the development of new aluminium window and door systems supporting the building sector.

HL: What are the keys to your companies’ success?

CM: “We are big on R&D, we invest in our people and technology to deliver exceptional service across our supply chain. We are safety focused and forward thinking in all endeavours we undertake”.

Read more at alspec.com.au