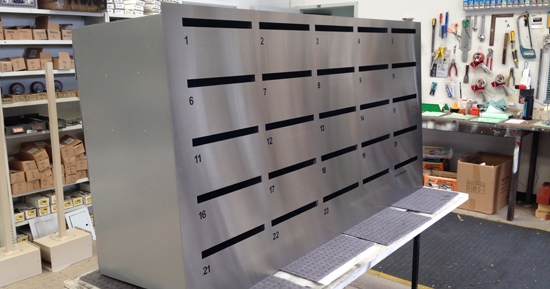

Adelaide Letterboxes has a 15 year history supplying customised letterboxes to customers around Australia. Andrew Stevens Managing Director of Adelaide Letterboxes bought the business in 2012 from founder David Wood.

Since taking over, Andrew recognised that the best way to manage and increase production was to invest in the right machinery.

Andrew recently purchased a Maxiem 1530 from Headland Machinery. The 1530 sets a higher standard for precision abrasive waterjet machining. It can cut impressive workpieces from virtually any material at significantly faster speeds and increases product output.

“In terms of (business) size we are about the same but our productivity has increased,” Andrew says.

“When I took over the business lead times were about 2-3 weeks,

“As more and more orders came in, our lead time went out to an embarrassing 4-5 weeks, but still the same turnover.

“Since then we have increased production brought lead times back down to 3 weeks – this is due to increase casual staff hours, better time management and the water jet machine,” he says.

Jake Malycha from Aussie Sheet Metals manages the manufacturing arm of the business. Since the purchase of the waterjet, Jake has seen a significant improvement in production efficiency.

“Aussie Sheet Metals and Adelaide Letterboxes have been doing business together for 8 years,” Jake says.

“The waterjet has been a massive help with speeding everything up,

“A batch of 100 units used to be manufactured by hand, which would take 2-3 people 3 days to make, now (with the waterjet) one person can produce twice as many in a day and a half.

“Out of all other machines the waterjet has provided a lot of versatility,” he says.

To find out more information on Adelaide Letterboxes click here.